Hey everyone!

Dave here with another technical write up! Today we're going to discuss Knock Retard and what it means to you as the driver

Index

If you're already aware of the differences, then feel free to skip it, or even if you know. A refresher never hurts!So let's move on, we see a lot of emails and customer posts on our Facebook group over Knock Retard, so let's dive a little into what that is, what triggers it, what you can do to remedy it, and most importantly when you should worry about it.

How it worksThe engine's ignition system operates on what we call a "Closed Loop", all this essentially means is that there are no breaks in the system and that feedback is being sent to the ECU.

As the tuner, we make ignition timing tables for the engine to run under various operating conditions, and to help make sure the engine runs with maximum power and efficiency, that timing is near the knock threshold of pump gas. To do this safely, there is a knock sensor to provide feedback and reduce timing when needed. The knock sensor can adjust or trim the ignition timing in the tune by a significant amount (up to 14.6 degrees) to ensure the engine doesn't encounter dangerous conditions.If your car has Knock Retard, it doesn't mean that the engine is knocking (as seen in the Cobb video above) all it means is that the knock sensor is picking up some type of noise and is trimming the ignition advance out of the system.

The sensor is calibrated to listen to very specific sounds, so don't worry, if your car hears you want pizza for lunch, it won't pop up on your MMI as a suggested location. (Bad joke.. I know)

The sensor is calibrated to listen to very specific sounds, so don't worry, if your car hears you want pizza for lunch, it won't pop up on your MMI as a suggested location. (Bad joke.. I know)

During engine operation, certain noises are known to be from detonation, and the sensor is calibrated to listen to those specific frequencies. You may have heard some of the old boys at the race track call it "ping" or "spark ping" well that's because with something as simple as a screwdriver being used as a "bushcraft stethoscope" you could listen to the engine make a pinging noise as it runs.

A loose downpipe bracket could make a vibration that gets transferred into the block and thus into the knock sensor which may lead to ignition timing being pulled. Let's say the downpipe only rattles or vibrates at that specific frequency in 3rd gear at 3200rpm while going downhill in vacuum (no boost). It's highly unlikely that the engine is knocking under those conditions, but you get back from your drive and see the "min/max" on your AccessPort picked up -4.88° of knock retard and now you're on the phone reaching out to EQT Support thinking your car is knocking.

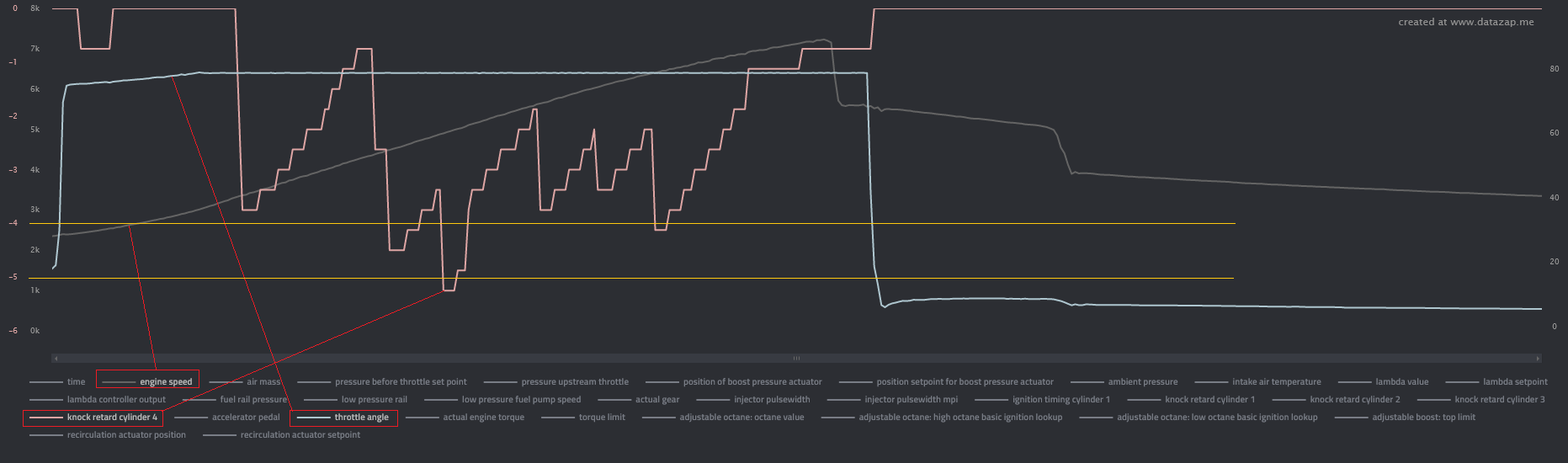

Above is an example of sustained knock events on a cylinder. The picture may be difficult to see, but the only monitors in view are knock retard cylinder 4, engine speed, and throttle position. Here you can see knock retard as much as -5.25 degrees, and several instances of -3.5 to -4.25 degrees of timing for knock.

Above is an example of sustained knock events on a cylinder. The picture may be difficult to see, but the only monitors in view are knock retard cylinder 4, engine speed, and throttle position. Here you can see knock retard as much as -5.25 degrees, and several instances of -3.5 to -4.25 degrees of timing for knock.

The threshold for where you may want to be concerned about KR comes down to if the KR is sustained, consistent, and repeatable, as well as the fuel type. Of course, everyone's car will vary, so use this as a guideline and not the end all be all. If you have concerns, reach out to our support team and have a log ready for review.

If your car is on 91 or 93 octane pump gas, generally speaking, anything more than 3° of KR and sustained may be a reason to dig into it a little deeper. Fuel quality also plays a huge role into if your car will see KR on pump gas. Ethanol free fuel will likely see KR before E10 (normal USA Standard). We do not recommend the use of ethanol free fuels, because despite the same octane rating, their resistance to detonation in the real world is significantly below their E10 counterparts.

If you're on Ethanol, including blends as low as E30 and see sustained knock retard of -3° or less, you may want to dig a little deeper into the car and look for any loose components, any rattles, etc. Ethanol is highly knock resistant and you'll likely reach the maximum effective timing (MBT) before you reach the knock threshold of Ethanol.

Another condition where KR may occur in values of 0° to -3° is during moderate to heavy acceleration in a high gear where the engine is being lugged such as passing on the highway in 5th gear. It's best just to downshift and allow the engine to utilize a higher part of the powerband to make the pass, then upshift again to 5th or higher.

- Worn spark plugs (the gap has grown wider than the suggested 0.024")

- Incorrect spark plugs ( not cold enough, or too cold for your setup)

- Worn out Ignition Coils (coils do start to wear over time and should be considered a maintenance item)

- Incorrect Ignition Coils (Aftermarket coils should be avoided. OEM works great)

- Damaged coil grounding wires (These often get twisted and may lose connection)

- Coil Grounding Stud Threads are damaged (soft aluminum vs steel. Steel wins every time)

EQT Talks About Spark Plugs - Technical Write up

- Defective PCV Valve / Plate (diaphragm often leaks on these and are hard to detect. Replace with the latest revision OEM PCV)

- Leaking or failed Diverter Valve (often throws a code, but not always. During a boost leak test you may feel air flowing around the DV indicating a bad seal)

- A Charge pipe / Coupler has come loose or is damaged (Boost leak test should reveal this)

- The N80 Purge valve is not operating correctly or the check valve is removed/installed incorrectly. (usually found on aftermarket catch can installations and the valve is installed incorrectly or is defective)

- Damaged / Cracked Intake Manifold

- Leaking Boost Tap (if you have a boost tap installed in the intake manifold it may be leaking around the o-ring)

- A boost leak test can be performed to help locate issues in the system.

- Fuel Injectors - DI. ( The DI Injectors are somewhat fragile and are prone to leaking, lower seal damage, etc. Particularly worse in 2019+ models with Continental injectors)

- Poor Fuel Quality (Pump gas can vary in quality from station to station, avoid the 'big box' stores such as Costco, Sam's Club, etc)

- HPFP not meeting target. (Typically found with aftermarket HPFPs or internals, this needs to be verified via logging Actual v. Requested)

- LPFP is unable to deliver sufficient fuel. (MPI cars will be able to log LP rail pressure, non-MPI cars will have to rely on HPFP pressure to determine if it's an LP supply issue.)

- The vehicle is low on fuel (heavy throttle should be avoided under ½ tank capacity due to fuel starvation issues with the OE tank design. Particularly worse on the FWD models)

- Loose bracketry (downpipe to block "lollipop", downpipe subframe bracket, etc)

- Engine Mounts (loose, incorrectly torqued, or worn out OE mounts may make vibration that can trigger the sensor)

- Damaged or incorrectly installed Harmonic Damper (highly unlikely, but possibly an issue)

- Lightweight flywheel/clutch (if its too light the chatter may be triggering the detection, however, this is highly unlikely)

- If you have a built engine, the difference in internal component weight may make additional noise or harmonics. If you're on a built engine your vehicle is likely custom tuned and the tuner will likely make provisions for this. (Consider investing in a Fluidampr)